Where to buy a hydraulic pump for garbage truck?

The easiest way is to contact the manufacturer of the machine (garbage truck) and provide the machine number and the part that needs to be replaced. This information should be included in the manual (the spare parts list). However, it often turns out this is the most expensive solution, and you have to wait several weeks for the pump. In such a situation, we suggest you contacting our power hydraulics specialists.

How to find the original hydraulic pump or its replacement?

You can use the search engine in our online store. To do this, simply enter the pump code in the search box or open the Garbage truck pumps category. If the code is not in the store, you can contact us via contact form.

Searching for pumps on the hektos.eu website

Searching for pumps on the hektos.eu website

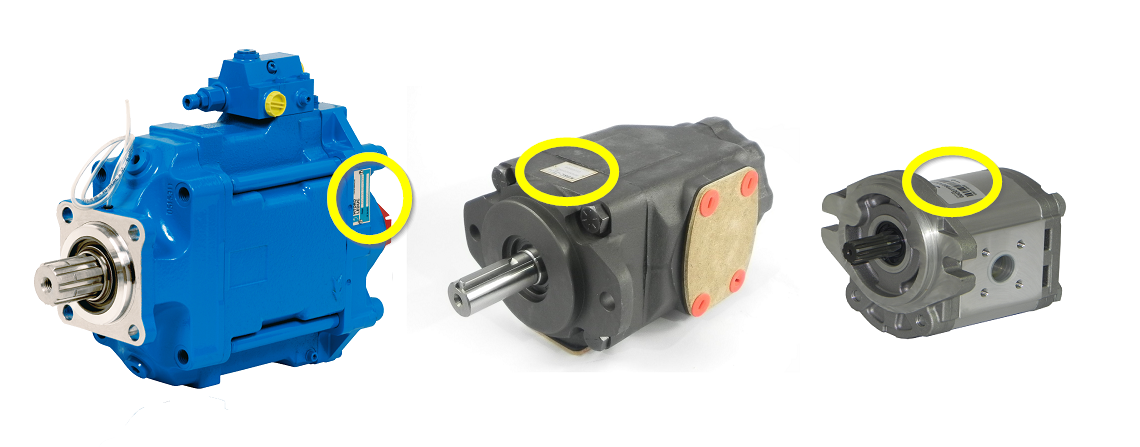

Each element of the hydraulic system drive (pump, motor, valves, filters) should have a name plate mounted on the body of this element. The name of the manufacturer and the code on the plate make it much easier to identify the pump. This is one of the first steps in selecting a pump. In addition, photos of the entire pump are also useful. Photos and the code of the pump can be sent to our specialists, who will check the parameters of the pump and its installation dimensions. On this basis, they will suggest you a new pump. The installation of the hydraulic system in garbage trucks is limited by a small space and finding the code on the hydraulic pump will probably require disassembly of the pump.

Location of name plates on pumps (from left to right): piston, vane and gear pumps

Location of name plates on pumps (from left to right): piston, vane and gear pumps

Vane pump cartridges identification

We have added a facility to the website, i.e. instruction for identifying the inserts of vane pumps, which are very often installed in garbage trucks. The manual contains 4 steps to identify the cartridges and can be downloaded at this link: Vane pump cartridges identification.

What kind of hydraulic pumps are fitted to garbage trucks? How much does a new garbage truck pump cost?

The most common pumps in garbage trucks are vane and piston pumps. In addition, piston pumps can be available in versions with the transmission of the drive to the gear pump. Gear and vane pumps in garbage trucks are fixed displacement pumps, while piston pumps can be fixed or variable displacement. The most commonly used controller in variable displacement pumps are the LS (load sensing) or PC (pressure compensator) controllers.

If the vane pump body and shaft are not damaged, it is usually enough to replace only the cartridges and seals, which significantly reduces repair costs. In the case of piston pumps, replacing parts (e.g. pistons) is comparable to the cost of a whole new pump. Gear pumps are common pumps used in all hydraulic systems and are usually the least expensive to replace. Prices for new garbage truck pumps can be found in the Garbage truck pumps category.

Cartridges in a double-flow vane pump

Barrel with pistons in a variable displacement piston pump

How to avoid failure of hydraulic pumps in garbage trucks?

First of all, make sure that the hydraulic oil in the hydraulic system is clean and you do not exceed the maximum operating parameters of the pump. Each hydraulic system should be equipped with oil filters adapted to the components (pumps, valves, motors, cylinders, etc.) installed in a given system. Return filters are most commonly used, but pressure filters are also required for proportional hydraulics. Focusing on the pumps themselves, manufacturers provide the required minimum filtration classes according to the ISO, NAS or SAE scale in their catalogs:

- for Hydro Leduc piston pumps, the filtration class is 20/18/15 according to ISO/DIS 4406;

- for B&C vane pumps, the filtration class is 18/14 according to ISO/DIS 4406;

- for B&C gear pumps, the filtration class is 23/20 at operating pressure above 150 bar and 26/23 at operating pressure up to 150 bar according to ISO/DIS 4406.

Of course, you should also use suitable hydraulic oil with the right viscosity:

- for Hydro Leduc piston pumps, HLVP oil with viscosity between 10 to 400 cSt (optimal viscosity range: 20-30 cSt);

- for B&C vane pumps, recommended viscosity for mineral oils is 10 to 2000 cSt (optimal viscosity range: 10-108 cSt);

- for B&C brand gear pumps, the recommended viscosity is 15 to 92 cSt.

The maximum operating parameters of a given pump model can also be found in the catalogs of pump manufacturers. Often these parameters depend on the size of the pump itself. If there are doubts about the maximum continuous working pressure or flow rate, we suggest contacting our specialists via contact form.

is a brand of Hektos

is a brand of Hektos